Functional textiles - anti-mite textiles

Printing warp knitted fabric supplier

With the improvement of people's environmental protection and health awareness, not only the beauty and comfort of the products are emphasized, but also the functions of hygiene and health care of fibers and fabrics are put forward. For example, fibers and fabrics with anti-mite function have been obtained in recent years. A wider range of applications.

1.Dust mites and their hazards

Dust mites are a self-feeding cockroach that feeds on powdery substances, such as animal dander, flour, cottonseed cake, etc. The optimum temperature for growth and development is (25±2) °C, and the optimum relative humidity is About 80% of the rooms with air conditioning and carpet are a good living environment. Dust mites are mainly dust mite allergies, clinical manifestations of dust mite asthma, allergic rhinitis and allergic dermatitis. A number of large-scale epidemiological surveys have found that dust mites are the most important source of indoor allergens. It is estimated that 50% to 80% of asthma is caused by dust mites, and it can cause other allergic diseases such as hay fever.

2. Chemical flood control

Chemical anti-mite is the use of chemical methods to kill and repel aphids. The chemical anti-caries agents used include acaricides and snoring agents. The acaricide mechanism is to destroy the nerve function, epidermis, growth, development and reproduction of aphids to achieve the purpose of killing; the mites are to prevent the aphids from approaching or inhibiting their reproduction under the action of taste, smell and pheromones.

The finishing method is an early conventional treatment technology for anti-mite textiles, and the implementation methods include spraying, padding, coating and the like. The technology has a simple production process and a wide range of uses. The disadvantage is that the durability is poor, and the anti-caries property is weakened with use and washing. The current research uses microcapsule technology, bonding technology, cross-linking technology and other new processes, so that the anti-mite finishing agent can form an elastic film on the surface of the fiber, which can improve the performance of the anti-mite fabric and have better durability.

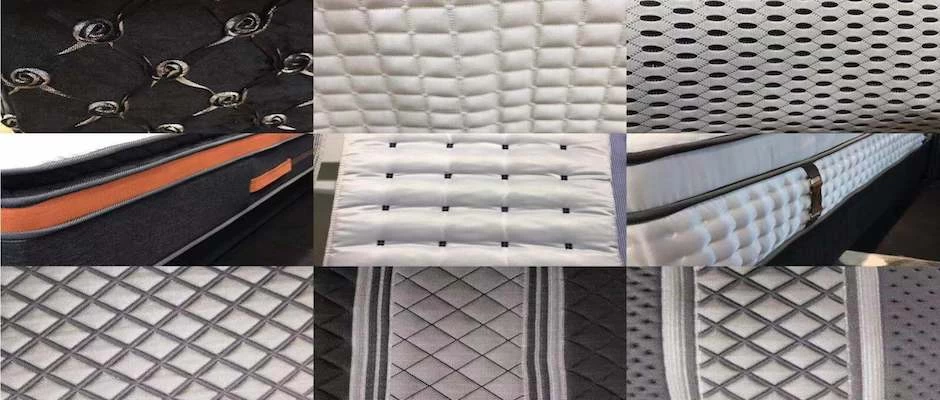

Mattress cover fabric wholesales

3. Physical defense

According to the filtration theory, the finer the fiber in the filter medium, the larger the specific surface area, the smaller the pore size, the better the filtration precision and the filtration efficiency. Therefore, by increasing the density of the fabric, the invasion of aphids or other allergens can be prevented to achieve the purpose of preventing cockroaches. For example, Japan Toray's anti-mite quilt is called "Klinik" high-density fabric, its anti-mite rate is 90%; in addition, the DuPont company's non-woven fabric "Tweed" and the German Freudenberg microfiber cloth "Ivo珑" are all such products. The physical anti-caries method can avoid or reduce the use of chemical agents and has a long lasting anti-caries effect. However, this method mainly relies on the weaving of the fabric itself or the microporous structure to prevent the intrusion or passage of the aphids, and the inability to repel or kill the aphids.

4. Natural fiber anti-mite

Bamboo contains a unique substance "bamboo", which has natural antibacterial, anti-mite, deodorant and insect-proof functions. Although the bamboo pulp fiber has been destroyed during the processing, the deodorization, antibacterial and anti-ultraviolet functions of the fiber are obviously reduced, but the test proves that the bamboo pulp fiber still has good antibacterial and anti-caries properties. Kapok fiber has a high hollow ratio (86% or more), closed ends of the fiber and good thermal insulation. The researchers believe that the surface contains a layer of wax is the main reason for the antibacterial and anti-mite function of kapok fiber. The test shows that the anti-caries rate of kapok floc reaches 90%, the anti-caries effect is excellent, and it can be used as a home textile product(Home textile fabrics manufacturer), etc. The outlook is good.