"The most fiber" in textiles, ready to go up knowledge!

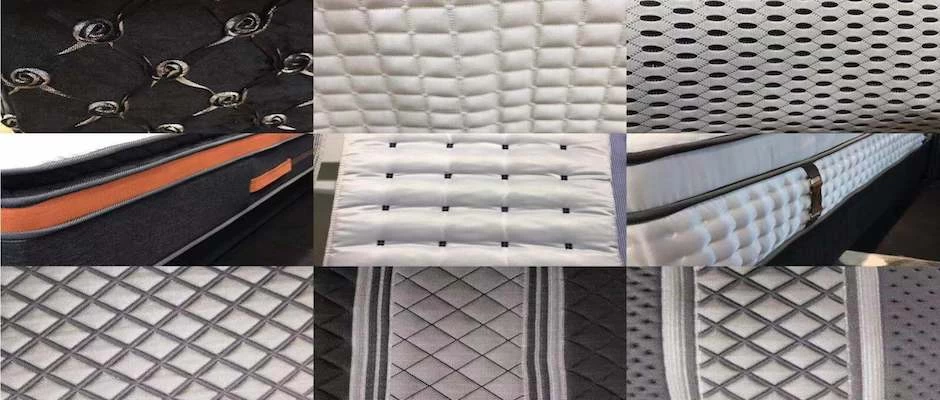

Stichbond polyester fabric manufacturer

First, the strongest is polyester

The strength of polyester fiber is two times higher than cotton and three times higers than tool. Impact strength four times higher than nylon, twenty times higher than ciscose.It is strong and strong, and the strength of the dry and wet states remains the same. Polyester fiber fabric is particularly crisp, smooth and not wrinkled.

Second, the most wearable is nylon

Nylon alias nylon. Its wear resistance is about 10 times that of cotton and 20 times that of wool. Because nylon wear resistance is higher than all textile fibers, nylon fabrics are durable.

Third, the most durable is acrylic

Acrylic fiber is fluffy, soft, warm and elastic, and is known as "synthetic wool". Because acrylic has a strong light resistance, higher than all other textile fibers, the textile industry changed the “nitrile” to “clear”, meaning it is not afraid of drying. It is exposed to outdoor exposure for one year and its strength is only reduced by 20%.

Waterproof membrane manufacturer china

Fourth, the most flexible is spandex

The elasticity of spandex fiber is usually 500%-800%, and the elastic recovery is also very good. Only about 2% of the spandex core-spun yarn fabric has an elastic elongation of 20-30%, which can achieve human body action on fabric elasticity. Requirements. Permanently maintain the original shape, comfortable and beautiful.

Fifth, the lightest is polypropylene

Its weight is only 3/5 of cotton, and in terms of "light", it is second to none in textile fibers. Polypropylene fiber is cheap and inexpensive. (Mattress printing polyester tricot fabric)

Sixth, the most afraid of heat is the polyvinyl chloride

Softening shrinkage starts at around 70 °C, and the shrinkage rate in boiling water can reach 50%, which is the most afraid of heat. Generally, once the fiber is ignited, it will still burn after leaving the open flame, and once the gelon leaves the open flame, it will naturally extinguish. Therefore, polyvinyl chloride is the most difficult textile fiber to burn.