Do you really understand fashion: Warp knitted fabric

hya

hya.com

2018-03-22 10:52:36

Do you really understand fashion:

Warp knitted fabric

1. Imitation leather warp-knitted outerwear Face-lifted fabrics Such fabrics have received attention in the 20th century, but the real development is in the last two or three years. This also reflects the progress in fiber manufacturing technology and fabric finishing technology. Artificial suede fabrics are also known as suede. This is a kind of superfine fiber material with short suede and fine hairiness. The appearance is similar to that of suede. It is a good face coat. Artificial suede has a long history in China. Since the 1970s, Japan has succeeded in producing microfibers. After the original Mi Dou was introduced, it was also trial-produced in China. However, due to the original Mi Dou finishing technology Promotion. However, it was of great creative significance to replace the coating with a water-soluble polyurethane at the time. The artificial suede now produced is generally made of polyester island microfibers. Commonly used three-comb Tricot machine to woven into a stable and stable fabric.

After shaping, the fabric is pretreated (often referred to as a reduction) to remove stains and inclusions on the surface of the fibers, allowing the fibers to be in an ultra-fine state and then dyed. There is a kind of process that properly fluffs the dyed grey cloth, then dries the polyurethane resin and then dries it, and then performs a buffing treatment to obtain a fine, dense, leathery fabric. The key to finishing is first of all to go beyond the sea component of the fiber to ensure that all microfibers are loose. The second is polyurethane resin finishing to ensure a good leather texture. In addition, it is necessary to carry out anti-static finishing to eliminate static electricity and dust absorption on the surface of rice. Artificial suede is generally produced on the E28's Tricot machine. Now E32 and E36 are used to get finer suede and improve the grade of the product. In addition, further improvement is required on the finishing. 2 imitation leather coating bucket With the decline of popular leather clothing, imitation leather fabric came into being, the reason may be low prices, for coats, coats of the firm features, arbitrarily designed glossy color appearance. Generally this kind of fabric can use conventional polyester. High-shrinkage fibers and microfibers are used as ground cloths, so as to achieve compactness and stability. The use of full-laying weft insertion machines can achieve the best requirements. The commonly used coating is PVC resin, which can be obtained in various colors and pattern patterns. It can also be coated with PU resin, and various convex and concave patterns can be rolled to make luggage materials.

Burnt-out warp knitted fabrics

It is interlaced with polyester and cotton yarn (or rayon, or man-made cotton yarn), and the sphaer is printed on a certain pattern with a printing machine, and the fibers and prime fibers printed at the place are rotted by concentrated sulfuric acid, and the holes are left only from the polyester, and the polyester is still preserved. Cotton interweaving forms a pattern, the effect of which is similar to that of multi-card lace-type fabrics. If a full-laying warp-knit warp knitting machine can be used, the polyester warp yarns are simply organized, and the cotton yarn or the human cotton spun yarns are used as the weft yarns. Burning with this ground cloth will have a very good effect. Women's fashion and decorative fabrics, lace lace. NUS eyelet fabrics are made of simple weaves made of warp knit fabrics, and can also be stitched with woven fabrics. It is also popular to make summer women's fashion.

3, Jacquard style fabrics with Jacquard jacquard performance, forming a unique pattern of the outerwear fabric. D-cotton yarn Jacquard T-shirt fabric This type of fabric is made of polyester cotton spun yarn as a dough on the polyester fabric, and uses Jacquard pattern hole, thin area, thick area to arrange according to the pattern, forming a unique flower pattern, wearing Comfortable men's and women's T-shirt fabrics are now generally produced on Jaka machines with E14 or larger gauges. In the blending of acrylic yarns or wool nitriles, it is possible to use only the thin and thick areas of the Jaca flower pattern to create warmer long-sleeved T-shirt fabrics. There have also been seen the use of rayon and wool.

Blended yarns.

Jaka Dyed Fabrics This is produced by the RJWB series Jakarska Shermer. A typical model is

RJWB3/2F type, this kind of machine has a compression yarn board, followed by a ground yarn comb and a weft-inserting jacquard comb in the press board, and these two cooperate to form the ground pattern of the complex pattern of the fabric, and there is a press yarn in front of the press board. The Jacquard comb and the single yarn selection device (EFS) cooperate with it to form a three-dimensional embossed pattern (the meaning of WB in the model) on the thin transparent ground. Since a single-yarn selection device is used for the front Jacquard comb of the press plate, each Jacquard yarn can be selected to enter or exit the work in the corresponding course, so that a separate embossed pattern segment can be formed and connected in the longitudinal direction. The line segment has been cut. Therefore, the fabric is very similar to the multi-comb mechanism with Jaka. It can be used as a high-end female fashion fabric, and can also be used with an extra spandex comb to produce elastic fabrics to suit the needs of high-end lingerie, swimwear, and bras. The model will be RJWB4/2F. This system also has RJWB8/2F type, then the increased comb can be used to expand the multi-card pattern, or to make a four-comb elastic mesh cloth. Another RJWBS4/2F type and RJWBS5/1F type. These machines were used to produce lace (indicated by S). The former had two Jacquard combs. The latter had only one Jacquard comb in front of the embossing board, and the Jacquard behind the embossed plate was replaced by two Combers. Therefore, its organization is simple. The RJWB series machines are fully computer-controlled and expensive. They are comparable to the 56-78 comb-Jakka machines.

4. Faux silk-like warp-knitted fabrics Faux silk and faux-hair are mostly achieved by suitable raw materials and finishing methods. Most of the D-fibre warp-knitted fabrics use triangular section fine denier (DPF equal to 1 or so), after woven into a dense grey cloth with a Tricot machine, alkali reduction treatment is used in the finishing process to achieve the desired gloss of the polyester filaments. And soft feel, generally after the printing, do female fabrics, skirt material. In the trial production of imitation silk warp knitting products, we must explore the application of pleated pleats to create a unique style of warp knitwear. @ Faux-knit warp knitted fabrics Most of our country's faux-wool filaments use ATY (air textured yarn). Most of them are used for woven fabrics, and some are not well done. The effect is not ideal. It should not be too difficult to knit on a tongue or slot needle warp knitting machine and should be explored. The multi-filaments that have emerged in recent years can achieve some single fibers in the same filament

With different sections, different thicknesses, and different shrinkages, after woven into a grey cloth, some fibers with a high shrinkage rate in the post-finishing process shrink, and the less-shrinking fibers are swollen, giving the fabric a wool fabric style. To increase the dimensional stability of the fabric, three combs can be used. Polyester microfiber and cotton blended yarns are now available in a variety of proportions. Fabrics have a certain cashmere style and can be researched, developed and applied.

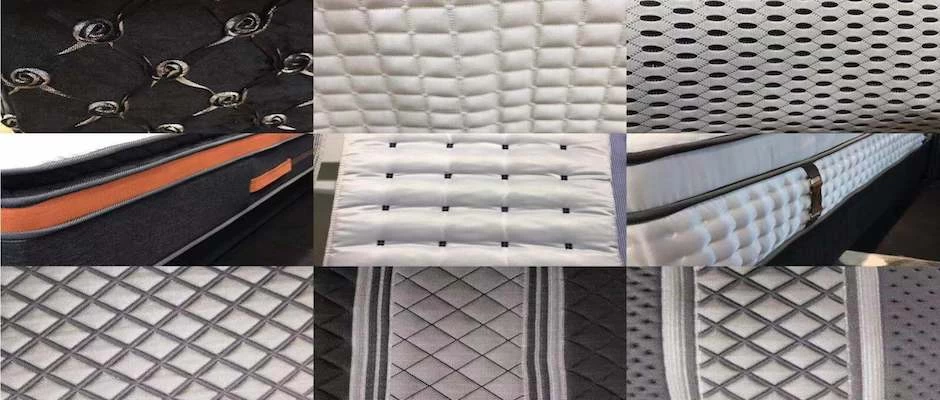

HEJIANG HYA INDUSTRY CO.,LTD is a trading and industry company which was built up at 2008 specializing in exporting and purchasing to more than 15 countries .

Main products: mattress cover, jacquard mattress fabric (damask fabric, strech knit), printing mattress fabric (tricot ,satin,pongee ,brush ,T/C ), Stichbond fabric,fireproof fabric,waterproof memebrane and so on.

Phone: 0086-575-88039102

Fax: 0086-575-88132184

Moble: 0086-13515755047

Contact: Chen NANCY

EMAIL: hyanancy@gmail.com

Main products: mattress cover, jacquard mattress fabric (damask fabric, strech knit), printing mattress fabric (tricot ,satin,pongee ,brush ,T/C ), Stichbond fabric,fireproof fabric,waterproof memebrane and so on.

Phone: 0086-575-88039102

Fax: 0086-575-88132184

Moble: 0086-13515755047

Contact: Chen NANCY

EMAIL: hyanancy@gmail.com