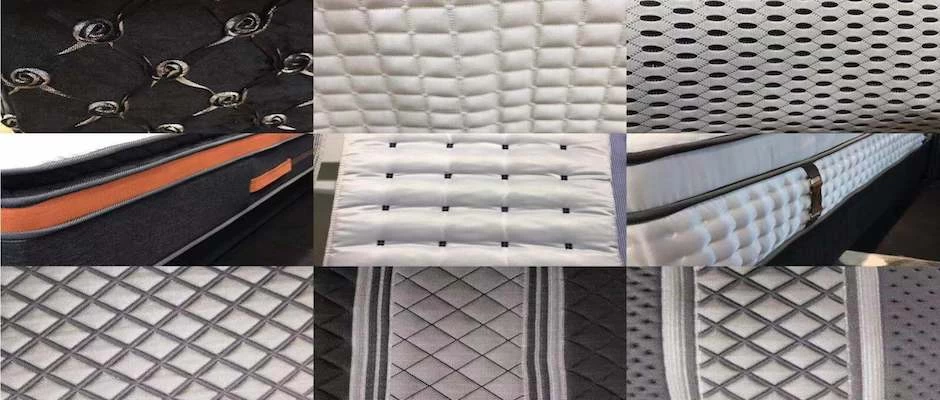

The difference between knitted fabrics and woven fabrics Knitted fabrics and woven fabrics

hya

hya.com

2018-04-20 19:56:00

The difference between knitted fabrics and woven fabrics Knitted fabrics and woven fabrics

The structure of the fabric structure:

(1) Knitted fabrics: The yarns are sequentially bent into coils, and the coils are interlaced with each other to form a fabric, and the process of forming the coils by yarns can be performed horizontally or longitudinally. Weft knit fabric, and longitudinal weaving is called warp knit fabric.

(2) Woven fabric: It is composed of two or more sets of mutually perpendicular yarns, which are interlaced with warp and weft at an angle of 90 degrees. Longitudinal yarns are called warp yarns, and transverse yarns are weft yarns.

Basic units of fabric organization:

(1) Knitwear: The coil is the smallest basic unit of the knitted fabric, and the coil is composed of a space curve and a spatial curve.

(2) Woven Fabric: Each intersection between the warp and the weft is called the tissue point and is the smallest basic unit of the woven fabric.

(3) Fabric texture characteristics:

(1) Knitted fabrics: Since the loops are yarns that are bent in space, each loop consists of one yarn. When the knitted fabric is subjected to external tension, such as longitudinal stretching, the loops The bending changes, and the height of the coil increases, while the width of the coil decreases. If the tension is transverse stretching, the situation is the opposite. The height and width of the coil can obviously be converted to each other under different tension conditions. The extensibility of the material is great.

(2) Woven fabrics: Because warp yarns and weft yarns are intertwined with some bending, and the crooks bend in a direction perpendicular to the plane of the fabric, the degree of bending thereof is related to the mutual tension between the warp and weft yarns, and the stiffness of the yarn, when the shuttle is subject to External tension, such as stretching in the longitudinal direction, increases the tension of the warp yarn and decreases the bending, and the bending of the weft yarn increases, such as the longitudinal stretching, until the warp yarn is completely straightened, and the fabric shrinks laterally. When the woven fabric is stretched laterally by external tension, the tension of the weft yarn increases, bending decreases, and warp yarn bending increases, such as horizontal stretching, until the weft yarn is completely straightened, and the fabric is longitudinally contracted. In the warp, weft yarns do not change, unlike knitted fabrics.

(D) The characteristics of the fabric structure:

(1) Knitted fabrics: can be extended in all directions, elasticity is good, because the knitted fabric is formed by the hole-shaped coils, has a larger breathability, feel soft.

(2) Woven fabrics: Because of the shuttle fabric weft, extension and shrinkage of weft yarn does not change much, and no change occurs. Therefore, the fabrics are generally relatively compact and stiff.

Physical and mechanical properties of fabrics:

(1) Knitted fabrics: physical and mechanical properties of the fabrics, including longitudinal, crosswise, square meters, elongation, elasticity, breaking strength, abrasion resistance, hemming, Thickness, dispersibility, shrinkage, coverage, bulk density.

(2) Woven fabrics: The physical and mechanical properties of woven fabrics, including the yarn density of warp and weft yarns, the edge of the fabric, the front and back sides, the direction of the back and forth hair, and the coverage of the fabric.

If you want to read more information about fabrics, please click the link Mattress anti slip fabric.

Zhejiang Hya Industry Co., Ltd.

Moble: 0086-13515755047

Contact person: Chen NANCY

E-MAIL: hyanancy@gmail.com

Zhejiang Hya Industry Co., Ltd.

Moble: 0086-13515755047

Contact person: Chen NANCY

E-MAIL: hyanancy@gmail.com