One minute little knowledge: What textile technologies include?

hya

hya.com

2018-04-16 16:24:25

One minute little knowledge: What textile technologies include?

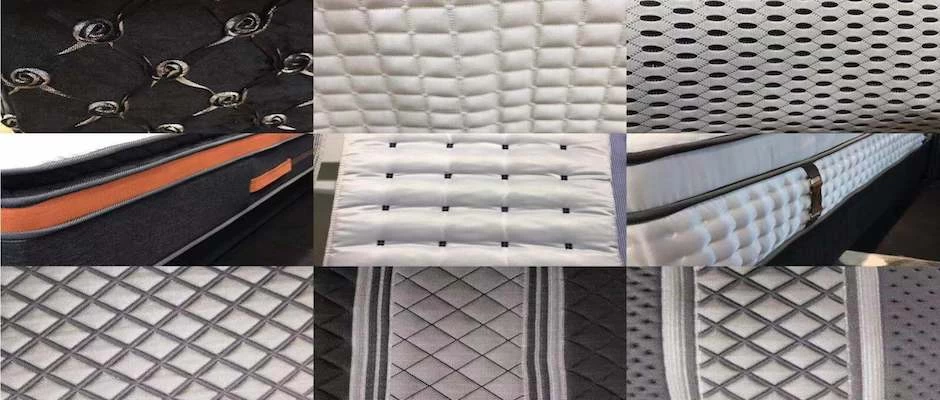

Non-woven fabric (NonWoven), also known as non-woven fabric, is composed of oriented or random fibers. It is a new generation of environmentally-friendly materials that are moisture-proof, breathable, flexible, lightweight, non-combustible, easily decomposed, non-toxic, and non-irritating. Sex, colorful, low cost, recyclable, etc. If more use of polypropylene (PP material) pellets as raw materials, the high-temperature melting, spinning, shop outline, hot-press coiling continuous one-step method of production. It is called cloth because of its cloth's appearance and certain properties.

The weaving technology of modern three-dimensional braided composite materials is basically based on the traditional textile technology. Each spindle is driven by the angle guide wheel and is transferred from one corner guide wheel to another adjacent corner guide wheel at the intersection point. The continuous repetition of the process allows each spindle to move on the trajectory of the interconnected number 8 so that the yarns interweave and cross each other to form the fabric.

If you want to read more information about fabrics, please click the link Spring matterss jacquard fabric factory .

Phone: 0086-575-88039102

Fax: 0086-575-88132184

Moble: 0086-13515755047

Contact person: Chen NANCY

E-MAIL: hyanancy@gmail.com

Fax: 0086-575-88132184

Moble: 0086-13515755047

Contact person: Chen NANCY

E-MAIL: hyanancy@gmail.com